By Steven Ralston, CFA

OTC:PQEFF | TSX:PQE

READ THE FULL PQEFF RESEARCH REPORT

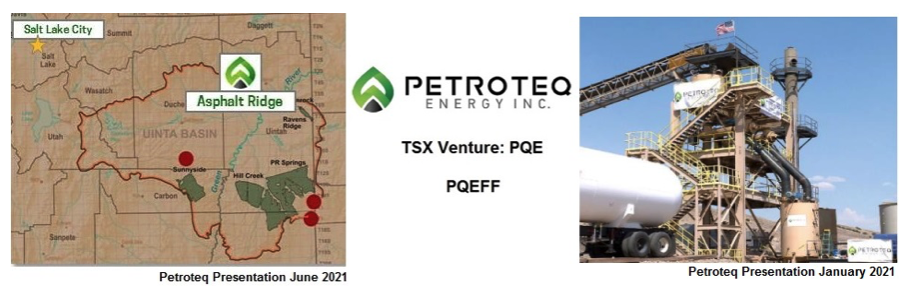

Petroteq Energy (OTC:PQEFF) (TSX:PQE) is an upstream exploration and production (E&P) company focused on advancing its proprietary Clean Oil Recovery Technology (CORT). Currently, the company is ramping up bitumen oil production at its recently upgraded and enhanced processing plant at Asphalt Ridge in Utah. A FEED study is anticipated to be released in July. JV partners of recent licensee Greenfield Energy, Valkor and TomCo, are actively involved to stimulate the advancement of the facility to commercial status. An unsolicited offer by Uppgard Konsult appears to give some indication about the potential and value of Petroteq’s Extraction Technology.

Petroteq Energy is advancing its proprietary Extraction Technology (CORT) for the development of heavy oil production from oil sands deposits worldwide, but initially in the Uintah Basin situated in Utah. The closed-loop extraction process is environmentally-friendly, and the modular processing plant, has been proven to be able to produce saleable heavy oil with low sulphur content at a low cost (around $30 per barrel). The company’s challenge is to engineer, construct and operate a commercial-scale plant that continuously operates 24/7 at a production run rate of 5,000 barrels per day (bpd). Multiple 5,000 bpd trains at a single location with shared infrastructure (both physical and services) could both incrementally increased production capacity and lower operating costs.

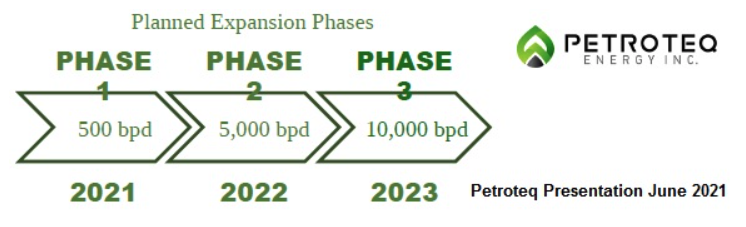

Management anticipates that production capacity will increase to 500 bpd by the end of 2021, 5,000 bpd in 2022 and 10,000 bpd in 2023. Achieving a continuous production rate of 10,000 bpd day would fully validate the commercial viability of the Petroteq’s proprietary CORT technology.

Petroteq’s CORT technology and the development of a commercial-scale plant have garnered significant interest from other companies in the space. Management is pursuing opportunities to license CORT technology to producers that have access to oil sands deposits and other heavy oil resources, not only in the Uintah Basin, but also elsewhere in the U.S. and internationally. To date, the company’s licensing agreements have been structured with a $2.0 million up-front licensing fee and a 5% production royalty stream.

Licensing Initiatives

Thus far, the following licensing agreements have been announced:

• TS Energy Ltd to act as exclusive licensee of CORT in Canada and the Republic of Trinidad and Tobago (May 2016)

• MOU with Queensland Energy & Minerals Pty Ltd for potential use of CORT on its Julia Creek Project in Australia (November 2017)

• Valkor LLC granted the non-exclusive, non-transferable use of the Petroteq’s Extraction Technology in the engineering, construction and operation of oil sands extraction plants worldwide (July 2019)

• Greenfield Energy LLC granted a non-exclusive, multi-site use of the Petroteq’s Extraction Technology in the engineering, construction and operation of oil sands extraction plants in the United States (November 2020)

Management has entered license agreements with partners in order to advance the development and deployment of its Extraction Technology. The financial, technical and operational commitments of Valkor LLC and TomCo Energy (through their joint venture Greenfield Energy LLC), in particular, provide strong indications about the achievability of developing of a commercial-scale plant. Along with the commitment of $2.0 million licensing fee, the JV has assumed the management and operational control of Petroteq’s processing facility at Asphalt Ridge.

Pre-FEED and FEED Studies

Currently, Petroteq is advancing the development of a 500 bpd test plant at Asphalt Ridge, which will lay the foundation for a 5,000 bpd plant or possibly multiple process trains to achieve a 10,000 bpd facility, which would fully validate Petroteq’s Extraction Technology. A pre-FEED (Front-End Engineering and Design) study that detailed the technical feasibility and economics of a 10,000 bpd production facility was completed in September 2020. The estimated capital cost of constructing the initial 5,000 bpd train is US$92.5 million. Utilizing shared infrastructure, a subsequent parallel 5,000 bpd trains is expected to have a lower cost. The estimated time from project sanction to the start of production is in the 15-to-17 month range.

Work on a full FEED study commenced almost immediately after the pre-FEED study was received and reviewed. Results from subsequent modifications and upgrades to improve the plant’s efficiency in late 2020 and early 2021 were incorporated into the FEED study. The draft of the full FEED study was received by management in June and is expected to be finalized after a verification review by a third-party. The results of the FEED study are anticipated to be released in July.

New Opportunity (Bunker Fuel)

New international shipping standards under IMO 2020 reduces the allowable sulphur content of bunker fuel (fuel oil used onboard ships) from 3.50% to 0.50% when operating outside designated emission control areas. This significant reduction opens a new market for Petroteq’s low sulfur bitumen oil as a feedstock in the blending process used by refineries to supply compliant bunker fuel. Approximately 5% of global oil production is used by the international shipping industry.

International Opportunities

Petroteq operates in Utah, which is estimated to contain 14 to 15 billion barrels of measured oil-in-place (OIP) in oil sands, along with an additional estimated bitumen resource of 23-to-28 billion barrels, on more than 700,000 acres of land, which is the largest concentration of bitumen-bearing sands in the United States. The Asphalt Ridge area, in particular, it is estimated to have 1 billion barrels OIP. The deposits tend to be near-or-at surface, allowing for much mining to be conducted with excavators and front loaders.

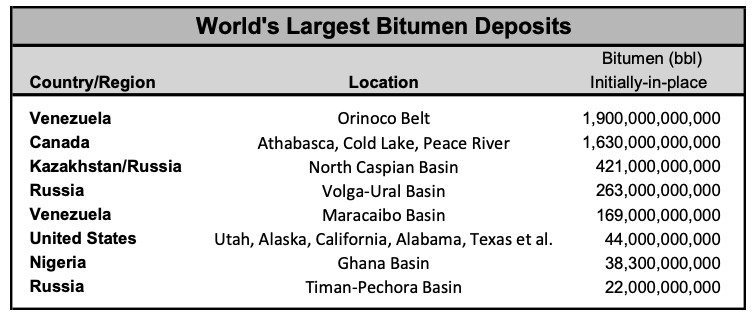

However, the potential for bitumen oil extraction in Utah is minuscule compared to the enormous opportunities internationally. Natural bitumen oil sands have been documented in 89 basins worldwide, which are estimated to contain 5.5 trillion barrels of bitumen OIP. Petroteq has been granted patents in the U.S., Canada and Russia, in which bitumen oil sands hold more than 2.3 trillion barrels OIP (or 43% of the estimated bitumen deposits worldwide).

Generally, defined bitumen resources are roughly 10% of OIP. Furthermore, approximately 10%-to-20% of defined bitumen resources are at or near-surface minable resources. Therefore, Petroteq’s addressable bitumen oil sands in the U.S., Canada and Russia are roughly 40 billion barrels.

Unsolicited Offer by Uppgard Konsult AB

On April 16, 2021, Uppgard Konsult AB, a Swedish company, made an offer to purchase up to 200 million shares of Petroteq at €0.48 per share. The minimum purchase is for 1 million shares. On June 29, 2021, the offer price was increased €0.50 per share, and the offering period was extended from June 30, 2021 to September 1, 2021.

The offer was posted in the Bundesanzeiger, the official Federal Gazette for official legal announcements in Germany. Petroteq’s stock trades on the Frankfurt Exchange under the ticker PQCF. The price as of June 30, 2021 was €0.11.

Management contacted Uppgard Konsult AB through their attorney, who made an inquiry via email. Uppgard Konsult AB responded that the offer is on behalf of an unidentified third party. Though Uppgard Konsult AB is primarily a private company operating in the forestry industry, the company also offers professional advice, actionable solutions and consulting services.

The offer appears to a legitimate, but not serious. It is legitimate in that it was officially made in the appropriate forum. The motive of the unidentified third party is unknown, but most likely it is an effort either to invest in a unique, proprietary technology that may be close to attaining commercial status OR to artificially increase the stock’s price.

However, given the stock’s unenthusiastic reaction, the offer does not seem serious. The offer is currently only applicable to shares traded in Germany, where PQCF was relatively illiquid. Daily volume averaged fewer than 10,000 shares prior to the offer and has been approximately 150,000 shares after the offer.

Also, the terms of the offer represent that the third party’s financial commitment is almost US$120 million (200 million shares at €0.50 each) for a minority position. If the offer were serious, a simultaneous offer in Canada, the U.S. and Germany for a majority, controlling stake of well over 230 million shares or more would be more logical.

Brief Company Developmental Summary

Petroteq is in the process of demonstrating the ability of its proprietary CORT oil sands recovery technology to commercially recover bitumen oil from oil sands in Utah. Proving the commercial viability of CORT would add a new chapter to the history of techniques developed to recover hydrocarbons. Since acquiring the ownership of this oil Extraction Technology in 2012, the advancement of the commercialization process has been moving ahead for almost a decade.

The initial stage involved the construction and operation of a proof-of-concept 250 bpd pilot extraction plant. Subsequently, between 2016 and 2018, in stage 2, an extraction facility was constructed at a location closer to the plant’s feedstock source (Temple Mountain Mine) in order to improve logistical efficiencies. In stage 3, management intends to further increase the heavy oil production rate to 5,000 bpd in 2022 and then construct an additional process train in the 2023 timeframe, bringing total production capacity at Asphalt Ridge to 10,000 bpd. It is anticipated that two process trains will share both various aspects of both hard and soft infrastructure, providing economies of scale.

Process Refinements

The process of advancing Petroteq’s Extraction technology has consisted of several time periods of modifications and upgrades to improve operational efficiencies. The three most significant periods were between 2014 and 2016 with the successful construction and operation of a proof-of-concept 250 bpd pilot extraction plant, between 2018 and May 2019 when the processing plant was relocated to Asphalt Ridge and expanded such that continuous bitumen oil production of over 500 bpd was achieved in mid-March 2019 and between September 2019 and March 2020 during which the plant generated revenues of over $290,000 and operated on a break-even basis for a time due to the improvements and enhancements implemented by Petroteq’s licensee, Valkor, since July 2019. Currently, the FEED study should help provide the basis for the next leap in the development of a commercial-scale processing plant. This step is different in that now Petroteq has the financial and technical support of Greenfield Energy JV (Valkor and TomCo Energy).

Through the years, the extraction process has encountered challenges and has been enhanced through certain engineering improvements. For example, a second separator (aka re-boiler) did not exist at the original pilot plant but was added to the new bpd facility at Asphalt Ridge in order to improve the API of extracted bitumen oil. In addition, considerable engineering effort was required to find the appropriate alloy for the fabrication of the propellers in the mixer in order to combat the erosive effect of sand. Another engineering improvement was the determination of the optimal angle for the propellers. Innumerable improvements and enhancements have been engineered and implemented over the years.

Re-Start of Production (2021)

After an unexpected COVID-19 restriction and the planned Christmas/New Year holiday shutdown, mining commenced on January 4, 2021, and soon thereafter, the ore began being processed at the POSP in mid-January. Through January 22, 2021, over 150 barrels of net oil in solvent had been produced. Management began fine-tuning the various plant systems (front-end movement of ore, crushing, mixing and extraction) in order to optimize the operations of the POSP. However, the ore being delivered to the plant had different physical characteristics (more clay fines) than that had been previously processed by the POSP. Additional enhancements were identified to address the ore situation, along with improvements to deal with the unusually cold weather recently experienced in Utah. Additional equipment was ordered. Delivery occurred in late-March, and installation was completed by mid-April. Production recommenced in the last week of April. Not only did the enhancements remove the clay fines, but also the efficiency of extracting bitumen was improved.

Between May 14 and May 21, processing of material was briefly halted by a Cessation Order by the Division of Oil, Gas and Mining (DOGM) of Utah. Operations recommenced under a modified CO within seven days. While the processing operations were on hold, a trial solids processing unit was integrated into the process stream.

Sale of Bitumen Oil

By June 3, 2021, 250 barrels of bitumen oil (API 10.2°) had been produced. The oil was tagged for sale, but due to trucking weight limitations, only 200.52 barrels were purchased and collected on June 11th. The buyer paid WTI pricing of US$70.91 per barrel, which demonstrates that a premium price versus other heavy oils can be realized by heavy, sweet (low sulfur). Transportation costs were US$13.00 per barrel to the refinery in Nevada, which resulted in a net realized price to US$57.91 per barrel. Net proceeds are estimated to be approximately US$11,600.

Greenfield Energy LLC Pursuing Acquisition of Oil Sands Property

On June 3, 2021, Greenfield Energy LLC entered into a membership interest purchase agreement with Endeavour Capital Group LLC and Tar Sands Holdings II LLC for the potential acquisition of up to 100% in Tar Sands II, which owns approximately 760 acres of land (in Uintah County, Utah), including an existing plant and equipment, along with a Large Mine Permit (No. M0470032).

After conducting due diligence and securing any necessary funding, Greenfield plans to use the site for the construction of a commercial-scale processing plant which will utilize Petroteq’s Extraction Technology. Greenfield already has paid a non-refundable deposit of US$200,000 for a 90-day period of due diligence. Greenfield now has a 120-day exclusive option to acquire 10% of the membership interests for US$2.0 million. The remaining 90% may be acquired by Greenfield for US$15.25 million by December 31, 2021, or for US$16.25 million if acquired thereafter but on or before December 31, 2022.

Current Management Expectations

The management of Greenfield expects that the oil sands mined from the Tar Sands II (which are anticipated to have a higher concentration of oil) can be processed at the POSP to help attain the targeted production level of 250 bpd. Shipments in the immediate future are anticipated to be priced around US$55 per barrel net of transportation costs. The most current rate of production announced in mid-June was 180 bpd as the oil extraction facility continues to operate in a test phase as production IS ramped up to 400 barrels per day. Any ramp up in production is conducted with a measured approach in order to help ensure that product quality will meet the standards expected by the company’s refinery customers.

Potential for By-Product Sales of Sand Tailings

In December 2020, Petroteq tested the clean sand tailings, a byproduct of the oil extraction process. The evaluation indicated that 60%-to-70% of the sand tailings are within a size range of 40/140 mesh with a crush strength over 8,000 psi, which is suitable for use as regional frac sand. Furthermore, 20% of tailings grade larger than 40 mesh, which can be used as an aggregate that adds structural integrity to cement in the making of concrete. The incremental revenue received from the sale of the clean sand tailings would increase the netbacks per barrel of oil produced.

Sale of Sand

In early June 2021, a truckload of cleaned sand (approximately 40 tonnes) was collected and shipped to a local drilling fluids company for evaluation. An additional 500-to-700 tonnes are available on-site. Pricing is anticipated to be in the US$15-to-$20 per tonne range with proceeds being retained by Greenfield Energy.

Value-added Post-processing MSAR® technology

A demonstration trial utilizing MSAR® technology is expected to be conducted by Quadrise Fuels International plc (LSE:QFI) in the post-processing sequence of Petroteq’s produced bitumen oil. Management anticipates that a sample of produced oil will be shipped to Quadrise in the UK for assessment by the end of June 2021.

MSAR is a power grade, synthetic heavy fuel oil, manufactured through a proprietary technology that mixes heavy oils with small amounts of specialty chemicals and water to create a low viscosity, emulsified formulation, which is environmentally-friendly since it burns almost completely with a minute amount of carbon particulate in the exhaust. The sale of MSAR fuel, which qualifies as a bunker fuel, generally adds 20% more value to untreated heavy oil. The required capex to implement MSAR has an expected payback of 12 months.

Indicated Target

Utilizing a traditional comparative valuation process based on the price-to-sales metric and a projected run-rate of year-end calendar 2022 sales, our share price target is $0.71 on a fully diluted basis.

SUBSCRIBE TO ZACKS SMALL CAP RESEARCH to receive our articles and reports emailed directly to you each morning. Please visit our website for additional information on Zacks SCR.

DISCLOSURE: Zacks SCR has received compensation from the issuer directly, from an investment manager, or from an investor relations consulting firm, engaged by the issuer, for providing research coverage for a period of no less than one year. Research articles, as seen here, are part of the service Zacks provides and Zacks receives quarterly payments totaling a maximum fee of $40,000 annually for these services. Full Disclaimer HERE.